Bulletproof vests serve as crucial protective gear, safeguarding law enforcement, military personnel, and even civilians from ballistic threats. The effectiveness of a bulletproof vest hinges primarily on the material from which it’s constructed. Different materials, including Kevlar, Ultra-High-Molecular-Weight Polyethylene (UHMWPE), Dyneema, Spectra, ceramics, and steel, each bring unique properties to the table, offering varying levels of protection, comfort, and durability. This article delves into a comparative analysis of commonly used bulletproof vest material, providing the necessary insights to make an informed decision on personal safety equipment. We’ll explore the evolution from ancient metal armor to modern synthetic fibers, highlighting the pros and cons of each, and offer guidance on selecting the right ballistic material for specific needs.

A Historical Glimpse into Ballistic Materials

The concept of body armor isn’t new. Throughout history, from the metal cuirasses of ancient warriors to the flak jackets of World War II, the quest for effective protection against projectiles has been constant. However, the modern era of bulletproof vests truly began with the development of high-strength synthetic fibers like Kevlar in the 1960s. This breakthrough marked a shift from heavy, cumbersome metal plates to lighter, more flexible ballistic materials.

Common Materials Used in Bulletproof Vests

Kevlar: The Pioneer in Bulletproof Vest Material

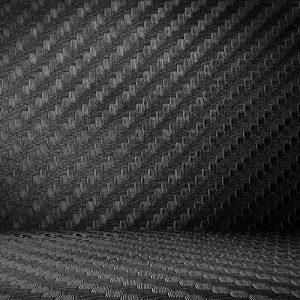

Kevlar distinguishes itself with its exceptional high tensile strength and lightweight properties, becoming a staple in law enforcement and military applications. In fact, studies have shown that Kevlar fabric possesses a tensile strength five times greater than that of steel on a weight-for-weight basis (DuPont, 2023). As a leading soft ballistic vest material, Kevlar’s flexibility allows for comfortable wear in both covert and overt vests, adapting to various body shapes.

Advantages

- Exceptional Tensile Strength: With a tensile strength exceeding 3,620 MPa (DuPont, 2023), Kevlar offers superior protection against ballistic threats. This high strength-to-weight ratio is why you’ll often hear “what is Kevlar?” followed by a discussion of its strength.

- Lightweight: The lightweight nature of Kevlar enhances mobility and reduces fatigue, making it suitable for extended wear. This is crucial for personnel who need to maintain agility while being protected. If someone asks, “what does Kevlar fabric feel like?” they’d often describe it as surprisingly light and flexible, especially considering its strength.

- Flexibility: Kevlar’s adaptability to different body shapes and sizes makes it a comfortable choice for various applications. It bends and moves with the wearer, offering both protection and ease of movement. You often find Kevlar in bulletproof vests because of this crucial feature.

Disadvantages

- Degradation Over Time: Kevlar’s protective capabilities can degrade over time, especially when exposed to UV radiation and moisture. Regular inspections and timely replacements, typically every five years, are essential to maintain its effectiveness. “Is Kevlar stab proof?” is a common question, and while it offers some cut resistance, it’s not specifically designed for stab protection, especially after degradation.

- Susceptibility to Moisture: Moisture can compromise the integrity of Kevlar fibers, reducing its ballistic performance. Proper storage in dry conditions is crucial.

- Cost: The advanced manufacturing process makes Kevlar relatively expensive, although many consider the superior protection worth the investment. “Kevlar bulletproof vest” cost is a factor many organizations consider, but the proven track record often outweighs the expense.

UHMWPE (Ultra-High-Molecular-Weight Polyethylene): The Lightweight Champion

UHMWPE, often recognized under trade names like Dyneema and Spectra (though Spectra is technically a specific type of UHMWPE), stands out for its exceptional weight reduction and enhanced mobility, making it a popular choice for thinnest bulletproof vest applications. It presents itself as a leading hard armor material, specifically in the form of UHMWPE plates, capable of defeating high-velocity rifle rounds. It is also widely used in soft ballistic vests as an alternative to aramid fibers.

Advantages

- Exceptional Weight Reduction: UHMWPE is significantly lighter than Kevlar, offering a noticeable advantage in mobility and comfort. UHMWPE fabric is particularly favored when weight is a critical factor. The difference in a “HDPE vs UHMWPE” comparison highlights this: UHMWPE has a much higher molecular weight, contributing to its superior strength and lightness.

- Enhanced Mobility: The lightweight nature of UHMWPE armor allows for quicker movements and greater agility, crucial in dynamic environments. “What are bulletproof vests made out of?” often leads to a discussion of the advantages of UHMWPE in modern armor systems.

- Improved Fatigue Resistance: By reducing the overall weight burden, UHMWPE helps personnel operate for longer periods with less fatigue.

Disadvantages

- Vulnerability to High Temperatures: UHMWPE is sensitive to high temperatures, which can degrade its integrity. Proper storage and usage guidelines are necessary to maintain its effectiveness. This limitation influences its suitability in extreme environments.

- Limited Availability: The complex and resource-intensive production process for UHMWPE can affect its availability and cost. While “UHMWPE bulletproof vest” options are growing in popularity, they may not always be as readily accessible as Kevlar-based vests.

- Performance in Extreme Conditions: While excellent against many threats, UHMWPE may not perform optimally against certain types of penetrators, particularly ogive-nose rounds, requiring a layered approach or combination with other materials in certain ballistic materials applications.

Dyneema: Strength and Durability Combined

Dyneema, a specific brand of UHMWPE, showcases an extremely high strength-to-weight ratio and remarkable durability. It’s often chosen when both high performance and longevity are desired. Its use extends beyond bulletproof vest material to ropes, nets, and other high-performance applications.

Advantages

- High Strength-to-Weight Ratio: Dyneema boasts one of the highest strength-to-weight ratios of any commercially available fiber, offering exceptional protection without adding excessive bulk.

- Resistance to Chemicals and Moisture: Dyneema is highly resistant to chemicals and moisture, extending its lifespan and maintaining its integrity in harsh environments. This makes it a reliable option for diverse operational conditions.

- Durability: Dyneema exhibits excellent durability, with stable performance in accelerated aging tests. This reduces the need for frequent replacements, providing long-term value.

Disadvantages

- Higher Cost: Dyneema’s advanced manufacturing process results in a higher cost compared to Kevlar, which can be a limiting factor for some budgets.

- Limited Flexibility: Compared to Kevlar, Dyneema can be more rigid, potentially impacting comfort and mobility, particularly in soft body armor applications.

- Performance at High Temperatures: Similar to other UHMWPE materials, Dyneema’s protective capabilities may diminish when exposed to extreme heat, necessitating careful consideration of the operational environment

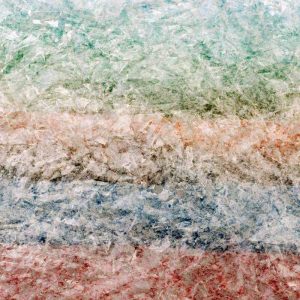

Spectra: Impact and UV Resistance

Spectra, another high-performance polyethylene fiber (like Dyneema, a specific type of UHMWPE), is highly regarded for its superior impact resistance and UV resistance. It is often utilized in hybrid armor systems, complementing other ballistic materials to provide comprehensive protection.

Advantages

- High Impact Resistance: Spectra fibers excel at absorbing and dispersing energy from high-velocity impacts, offering excellent protection against ballistic threats.

- Lightweight: Spectra is lightweight, contributing to reduced fatigue and enhanced mobility for the wearer. This is a crucial factor in prolonged operations or high-intensity situations.

- UV Resistance: Spectra maintains its integrity even when exposed to ultraviolet light, extending the lifespan of the vest and making it suitable for outdoor use.

Disadvantages

- Cost: Like Dyneema, Spectra’s advanced manufacturing process contributes to its relatively high cost, although its superior properties often justify the investment. The cost is a factor when considering “what are bulletproof vests made of” and budgeting for protective gear.

- Limited Availability: The production of Spectra is complex and resource-intensive, which can sometimes affect its availability in the market.

- Performance Under Extreme Conditions: While Spectra offers excellent UV resistance, it may not perform optimally under extreme temperatures, which can degrade its effectiveness.

Ceramic Plates: The Hard Armor Solution

Ceramic plates offer a high level of protection, particularly against high-velocity rifle rounds, making them a critical component of hard armor systems. They are typically used in conjunction with a backing material, such as Kevlar or polyethylene, to provide comprehensive protection. This combination answers the question, “what is swat armor made of?”—often a combination of ceramic plates and high-strength fibers.

Advantages

- High Level of Protection: Ceramic plates can effectively stop most high-powered rifle rounds, providing superior ballistic resistance compared to soft armor alone. “Is Kevlar bulletproof?” often leads to a discussion of its limitations against rifles, where ceramics excel.

- Ability to Stop High-Velocity Rounds: Ceramics work by shattering incoming rounds, dispersing their kinetic energy and significantly reducing the risk of penetration and injury. This makes them essential for facing higher-level threats.

- Durability: Ceramic plates often feature a tile composite strike face, which isolates damage to individual tiles, allowing the armor to withstand multiple hits.

Disadvantages

- Heaviness: Ceramic plates are considerably heavier than soft armor materials, which can lead to fatigue and reduced mobility, especially during extended use. This weight is a primary concern when choosing between different levels of protection.

- Bulkiness: The size and shape of ceramic plates can restrict movement and comfort, particularly in confined spaces or when agility is paramount. The trade-off between protection and mobility is a key consideration.

- Fragility: Ceramic plates can crack or break under stress, requiring careful handling and timely replacement if damaged. They are not as flexible or forgiving as fiber-based materials.

Steel Plates: Durability and Cost-Effectiveness

Steel plates present a durable and cost-effective option for hard armor protection, particularly in situations where cost is a major constraint. While heavier than other options, their robust construction provides reliable multi-hit capability. Common material for bulletproof vest in lower budget scenarios often include steel.

Advantages

- High Durability: Steel plates are exceptionally durable and can withstand significant impacts without shattering or cracking. Their robustness makes them a reliable choice for harsh environments.

- Cost-Effectiveness: Steel plates are generally less expensive to produce than ceramic or high-performance polyethylene plates, making them a budget-friendly option for armor.

- Multi-Hit Capability: Steel plates can endure multiple impacts without losing their structural integrity, enhancing their reliability in combat situations.

Disadvantages

- Weight: Steel plates are significantly heavier than other armor materials, which can lead to fatigue and restrict mobility. This is a major drawback, especially for prolonged wear.

- Potential for Spalling: Steel plates can produce dangerous fragments (spalling) upon impact, posing a secondary injury risk. Anti-spall coatings are often applied to mitigate this risk, but they add to the weight and cost.

- Comfort Issues: The rigid nature of steel plates can affect comfort, requiring additional padding and careful fitting to minimize discomfort and potential chafing.

Polyethylene Armor: Balancing Weight and Protection

Polyethylene armor, especially high-density polyethylene (HDPE), is valued for its lightweight design and excellent strength-to-weight ratio. It serves as a hard armor option, providing protection against rifle threats while minimizing the weight burden on the wearer. When considering “hdpe vs uhmwpe”, it’s important to note that while both are polyethylenes, UHMWPE offers superior performance due to its higher molecular weight.

Advantages

- Lightweight Design: Polyethylene armor is significantly lighter than steel and comparable in weight to some ceramic options, providing rifle-rated protection without excessive fatigue.

- Superior Strength-to-Weight Ratio: High-density polyethylene fibers offer excellent protection against ballistic threats relative to their weight, making them a popular choice for mobility-focused applications.

- Chemical and Moisture Resistance: Polyethylene armor resists chemicals and moisture, extending its durability and maintaining its performance in various environments.

Disadvantages

- Higher Cost: The advanced manufacturing process required for high-performance polyethylene armor results in higher costs compared to steel, although many users find the benefits worth the investment.

- Limited Flexibility: Polyethylene armor can be less flexible than soft armor materials, which may impact comfort and mobility, especially during dynamic activities.

- Performance in High Temperatures: Exposure to extreme heat can reduce the protective capabilities of polyethylene armor, necessitating consideration of the operational environment.

Armor Construction and Material Properties: Shaping Bulletproof Vests

The performance of a bulletproof vest hinges on two interconnected elements: its construction (soft or hard) and the specific bulletproof vest materials employed. Understanding how these factors interplay is crucial for answering the common question, “What are bulletproof vests made of?” and making informed decisions about personal protection. The manufacturing process of these ballistic materials further influences their final characteristics and effectiveness.

Soft Armor: Prioritizing Flexibility and Concealment

Soft armor excels in flexibility and concealability, making it ideal for situations where mobility and discretion are paramount. This construction relies on tightly woven, layered fabrics to create a material capable of dissipating the energy from handgun rounds and fragmentation.

- Materials and Manufacturing: Kevlar, a widely recognized material for bulletproof vests, exemplifies the typical soft armor material. Its manufacturing involves spinning liquid crystalline poly-paraphenylene terephthalamide into strong, flexible fibers, which are then woven into a tight fabric. Similar processes are used for other aramid fibers and specialized UHMWPE fabrics employed in soft ballistic vests. The weave pattern and the number of fabric layers directly influence the vest’s ability to stop projectiles. The resulting material is lightweight and comfortable, making “kevlar bulletproof vest” synonymous with flexible protection. However, newer ballistic materials like Dyneema, also created through advanced fiber spinning and weaving techniques, are gaining traction due to their even higher strength-to-weight ratios.

- Applications: Soft armor is favored by law enforcement, security personnel, and individuals seeking discreet protection. Its low profile and flexibility allow for comfortable wear under clothing and a full range of motion, making soft ballistic vests a practical choice for daily wear.

- Limitations: While effective against handgun rounds and fragmentation, soft armor offers limited protection against rifle rounds and edged weapons. It is also susceptible to degradation from environmental factors like moisture and UV exposure, requiring proper care and maintenance. Furthermore, while offering some blunt force trauma protection, it doesn’t eliminate the risk of injury from such impacts.

Hard Armor: Maximizing Ballistic Protection

Hard armor prioritizes maximum ballistic protection against high-velocity rifle threats. Its construction revolves around rigid plates, creating a strong barrier that soft armor can’t provide.

- Materials and Manufacturing: Hard armor plates leverage a variety of materials and manufacturing processes. Ceramic plates, a popular choice, are created by sintering ceramic powders (like alumina, boron carbide, or silicon carbide) at high temperatures to form a dense, hard material. This process results in plates capable of shattering incoming projectiles. Steel plates, manufactured through rolling and heat-treating processes to achieve hardness and toughness, offer a more cost-effective, though heavier, option. UHMWPE plates are produced by compressing and molding ultra-high-molecular-weight polyethylene into a rigid form. The manufacturing process determines the plate’s density and ballistic resistance, making “uhmwpe bulletproof vest” an increasingly common term for high-performance hard armor. Composite materials, combining different ballistic materials like ceramic and UHMWPE, are also utilized to optimize performance.

- Applications: Military personnel, SWAT teams, and others facing rifle threats rely on hard armor. It’s often used in conjunction with soft armor, combining the flexibility of a “kevlar bulletproof vest” with the stopping power of hard plates.

- Limitations: Hard armor adds significant weight and bulk compared to soft armor, which can restrict mobility and increase fatigue. The rigidity of hard armor plates can also impact comfort, requiring careful fitting and integration with the vest system. Ceramic plates, while highly effective, can be brittle and susceptible to cracking upon impact, potentially compromising their protective capabilities. Steel plates, while durable, can suffer from spalling, where fragments of the plate are projected upon impact, posing a secondary threat.

Ballistic Test Standards and Levels of Protection

To ensure that bulletproof vests provide the necessary level of protection, they are subjected to rigorous testing based on established standards. The National Institute of Justice (NIJ) in the United States sets the standards for ballistic resistance, classifying vests into different levels based on their ability to stop specific threats. These levels range from Level IIA, which protects against lower-velocity handgun rounds, to Level IV, which can stop armor-piercing rifle rounds. Understanding these levels is crucial when choosing a bullet proof vest material. Bulletproof materials are tested against various projectiles, including full metal jacket (FMJ) bullets, jacketed hollow point (JHP) bullets, and armor-piercing (AP) rounds. The tests measure the vest’s ability to prevent penetration and limit the depth of indentation (backface deformation).

FAQ: Addressing Common Concerns about Bulletproof Vests

What is the strongest body armor material?

There isn’t a single “strongest” material, as the effectiveness depends on the specific threat. Generally, hard armor plates, such as ceramic or steel, offer the highest level of protection against rifle threats, while high-performance polyethylene materials like Dyneema offer exceptional strength and light weight. For handgun threats, kevlar bulletproof vests remain a popular and effective choice. “What material is bulletproof?” often depends on the context of the threat being addressed.

Is Kevlar body armor illegal?

In most jurisdictions, owning and wearing Kevlar body armor is legal for civilians. However, some restrictions may apply to individuals with felony convictions. It’s essential to check local laws and regulations.

Can a bulletproof vest stop an AK-47?

Whether a vest can stop an AK-47 round depends on the vest’s protection level and the specific type of ammunition used. Level III and IV vests, typically incorporating hard armor plates, are designed to offer protection against rifle rounds, but certain AP rounds may still pose a threat. “What materials are bulletproof” enough for rifle threats requires careful selection based on NIJ standards.

What is the lifespan of a bulletproof vest?

The lifespan of a bulletproof vest depends on various factors, including the material, usage, and storage conditions. Most manufacturers recommend replacement every 5 years, but regular inspections are essential to detect any signs of wear or damage that may compromise its effectiveness. “What material is a bulletproof vest made of?” and “how is it stored?” are both crucial for assessing its remaining life.

How to choose the right bulletproof vest?

Choosing the right bulletproof vest requires careful consideration of several factors, including the threat level, comfort requirements, budget constraints, and operational environment. Consulting with experts and referring to NIJ standards can help in selecting the appropriate level of protection and material.

Future Trends in Bulletproof Vest Materials

The field of ballistic materials is constantly evolving, with ongoing research and development focused on creating lighter, stronger, and more flexible protective solutions. Nanotechnology, advanced composites, and smart materials hold significant promise for the future of bulletproof vests. These advancements aim to enhance protection while minimizing weight and maximizing comfort for the wearer. The ongoing exploration of materials science addresses common queries like “what are bullet proof vests made of” and “what is the strongest body armor material” by pushing the boundaries of protective capabilities. Further, advancements also drive inquiries into related products, such as “what is swat armor made of”, prompting the development of specialized protective gear.

Conclusion: Balancing Protection, Performance, and Practicality

Choosing the appropriate bulletproof vest requires careful consideration of the threat level, desired comfort, and operational needs. Soft armor excels in comfort and concealability but offers limited protection against rifles. Hard armor provides maximum ballistic protection but sacrifices mobility and adds weight. Understanding the properties of bulletproof vest materials like Kevlar, UHMWPE, ceramics, and steel, their manufacturing processes, and the different armor constructions allows for informed decisions that balance protection, performance, and practicality. Staying informed about advancements in ballistic materials ensures access to the most effective and comfortable personal protection solutions available.