Ballistic vests play a crucial role in personal protection, especially for law enforcement and military personnel. Understanding the engineering behind these vests is essential for enhancing their effectiveness and safety. The blog aims to delve into the intricate aspects of ballistic vest design and engineering, providing insights into the materials, principles, and advancements that make these protective gears indispensable.

Historical Background

Early Developments

Ancient Armor

Humans have sought armor for centuries. Ancient civilizations, such as the Romans and Greeks, developed early forms of body armor. These armors consisted of metal plates and chainmail designed to protect against bladed weapons and projectiles. Genghis Khan instructed his horsemen to wear silk vests underneath their armor. This practice aimed to protect against arrows during battle.

Evolution to Modern Ballistic Vests

The concept of bulletproof vests emerged in the late 1800s. A French army captain created the first ballistic vest to defend against enemy weaponry. Italian and Roman royalty also experimented with bulletproof vests. They built body armor with layers of metal to deflect bullets. The outer layer absorbed the bullet’s impact, while the inner layer stopped further penetration. World War II stimulated the development of lighter body armor. This armor consisted of overlapping plates of steel, aluminum, or bonded fiberglass within a nylon garment.

Key Milestones in Ballistic Vest Development

Introduction of Kevlar

The discovery of new fibers in the 1960s revolutionized ballistic vest technology. DuPont invented Kevlar ballistic fabric in the early 1970s. Kevlar’s high tensile strength and lightweight properties made it ideal for bullet-resistant vests. This innovation marked a significant advancement in personal protection.

Advancements in Material Science

Material science has continued to evolve. Researchers have developed composite materials like carbon-epoxy and spectra. These materials offer enhanced ballistic protection and reduced weight. The integration of ceramic and polyethylene plates has further improved the effectiveness of ballistic vests. These advancements have made modern vests more durable and comfortable for users.

Materials Used in Ballistic Vests

High-Performance Fibers

Kevlar

KEVLAR remains the most recognized material for making soft body armor. This man-made hydrocarbon fiber exhibits high strength and low weight. Chemical resistance and flame resistance further enhance its suitability for ballistic vests. KEVLAR fibers are tightly spun, providing a tensile strength ten times greater than steel on an equal weight basis. Manufacturers sew KEVLAR into vests and clothing to create effective protective gear.

Dyneema

Dyneema is another high-performance fiber used in ballistic vests. This polyethylene fiber boasts an extremely high strength-to-weight ratio. The lightness of Dyneema allows it to float on water. High energy absorption characteristics make Dyneema a popular choice among premium body armor manufacturers. The use of Dyneema in vests enhances both protection and comfort for the wearer.

Composite Materials

Ceramic Plates

Ceramic Plates play a crucial role in modern ballistic vests. These Plates provide excellent protection against high-velocity projectiles. The ceramic material shatters upon impact, dispersing the bullet’s energy and reducing penetration. Hard armor plates made from ceramic are often integrated with soft armor to achieve higher levels of ballistic protection. The combination of ceramic Plates and soft armor ensures comprehensive coverage for the user.

Polyethylene Plates

Polyethylene Plates offer another layer of protection in ballistic vests. These Plates are lightweight yet highly effective at stopping bullets. The high-density polyethylene material absorbs and disperses the energy from the bullet, preventing penetration. Plate Carrier Design often includes polyethylene Plates to balance protection and mobility. The integration of these Plates into vests enhances the overall performance and comfort for users.

Engineering Principles

Impact Resistance

Energy Absorption

Ballistic vests must absorb energy from projectiles to protect the wearer. Engineers use materials like Kevlar and Dyneema for their high tensile strength and energy absorption capabilities. These fibers deform bullets, spreading the force over a larger area. This process reduces the risk of penetration and minimizes blunt force trauma. Advanced materials like polymer nanocomposites and graphene sheets show promise in enhancing energy absorption. Researchers continue to explore these materials for future applications.

Distribution of Force

Effective ballistic vests distribute force across the vest’s surface. This distribution reduces the impact on any single point, enhancing protection. Engineers design vests with multiple layers of high-performance fibers and composite materials. Ceramic and polyethylene plates play a crucial role in this process. These plates shatter or deform upon impact, dispersing the bullet’s energy. This approach ensures comprehensive protection and reduces the risk of injury.

Design Considerations

Ergonomics

Ergonomics is vital in ballistic vest design. Engineers focus on creating vests that fit comfortably and allow for a full range of motion. Proper fit enhances the vest’s effectiveness and ensures user comfort. Modern vests incorporate adjustable straps and flexible materials to achieve this goal. The integration of lightweight materials like Kevlar Protera contributes to better ergonomics. These advancements make vests more wearable for extended periods.

Weight Distribution

Weight distribution is another critical factor in ballistic vest design. Uneven weight can cause discomfort and reduce mobility. Engineers design vests to balance weight evenly across the body. This approach minimizes strain on the wearer and enhances overall performance. The use of lightweight yet strong materials like Dyneema helps achieve optimal weight distribution. Innovations like the skeletonized plate carrier design further improve weight management. This design reduces unnecessary bulk while maintaining high levels of protection.

Ballistic Vest Design and Engineering

BULLETPROOF KEVLAR VEST

Structure and Composition

The structure of a BULLETPROOF KEVLAR VEST involves multiple layers of tightly woven Kevlar fibers. These fibers provide high tensile strength and flexibility. Manufacturers often use Kevlar 129 for increased ballistic protection. The composition includes an outer shell made from durable fabric to protect the inner layers from environmental factors. The vest’s design ensures optimal coverage of vital organs.

Performance Metrics

Performance metrics for a KEVLAR VEST include stopping power, weight, and comfort. The vest must meet National Institute of Justice (NIJ) standards for ballistic resistance. Tests measure the vest’s ability to stop various calibers of bullets. Weight plays a crucial role in user comfort and mobility. A well-designed KEVLAR VEST balances protection with wearability. Over 3,000 officers’ lives have been saved since 1987 due to the effectiveness of these vests.

IcePlate EXO

Integration with Ballistic Vests

The IcePlate EXO integrates seamlessly with ballistic vests. This hydration system provides cooling and hydration while maintaining protection. The IcePlate EXO fits into existing carrier designs without compromising the vest’s integrity. Users benefit from enhanced comfort during extended wear. The integration process involves securing the IcePlate EXO within the vest’s compartments.

Benefits and Limitations

The IcePlate EXO offers several benefits. It reduces heat stress and provides hydration, improving overall performance. The lightweight design does not add significant bulk to the vest. However, limitations exist. The IcePlate EXO requires regular maintenance and refilling. In extreme conditions, the cooling effect may diminish over time. Despite these limitations, the IcePlate EXO remains a valuable addition to ballistic vests.

ANALYSIS OF A BULLETPROOF

Case Studies

Case Study: Life-Saving Potential of Soft-Body Armor

A study in 1978 revealed that soft-body armor could have saved the lives of 37 officers. This case highlights the importance of effective ballistic vest design and engineering. The study focused on the performance of soft-body armor in real-world scenarios. Researchers analyzed incidents where officers faced gunfire. The findings emphasized the need for continuous improvement in vest technology.

Performance Analysis

Performance analysis of bullet-proof vests involves evaluating various factors. Engineers assess the vest’s ability to absorb and distribute force. The use of materials like Kevlar and Dyneema enhances energy absorption. Tests measure the vest’s resistance to different calibers of bullets. The analysis also considers ergonomics and weight distribution. A comprehensive approach ensures that the armor plates be exposed to rigorous testing. This process guarantees the vest’s reliability in critical situations.

DESIGN AND ANALYSIS

Design Methodologies

Ballistic vest design methodologies involve a systematic approach. Engineers begin with material selection, focusing on high-performance fibers like Kevlar and Dyneema. These materials offer superior tensile strength and energy absorption capabilities. The design process includes creating various protection zones on the front and back of the vest. Each zone receives specific attention to ensure optimal coverage and protection.

Engineers use advanced tools like Ansys for simulation and modeling. These tools help predict the vest’s performance under different conditions. The simulations allow for adjustments in the design before physical testing. This approach saves time and resources while ensuring the vest meets safety standards.

The integration of hard armor plates, such as ceramic and polyethylene, forms another critical aspect. These plates enhance the vest’s ability to stop high-velocity projectiles. Engineers must ensure that the plates fit seamlessly within the vest without compromising comfort or mobility. The combination of soft and hard armor provides comprehensive protection for the wearer.

Analytical Techniques

Analytical techniques play a crucial role in evaluating ballistic vests. Engineers employ the Finite Element Method (FEM) technique to analyze the vest’s performance. This method involves breaking down the vest into smaller elements and assessing their behavior under stress. The FEM technique provides detailed insights into how the vest absorbs and distributes force.

Ansys software facilitates these analyses by offering robust simulation capabilities. Engineers can model various scenarios and assess the vest’s response to different threats. This process ensures that the vest performs reliably in real-world situations.

Field testing complements these analytical techniques. Engineers conduct rigorous tests to validate the simulation results. These tests involve shooting at the vest with different calibers of bullets. The data collected from these tests help refine the design and improve the vest’s performance.

Case Studies:

-

Life-Saving Potential of Soft-Body Armor: A study in 1978 highlighted that soft-body armor could have saved the lives of 37 officers. This case underscores the importance of continuous improvement in vest technology. The study focused on real-world incidents where officers faced gunfire. Researchers analyzed the effectiveness of the armor and identified areas for enhancement.

-

Development and Testing of Kevlar Vests: Bulletproof vests have saved over 3,000 officers’ lives since 1987. This statistic demonstrates the effectiveness of Kevlar vests. The introduction of Kevlar 129 marked a significant advancement in ballistic protection. Engineers continue to refine the design and composition of these vests to enhance their performance.

The integration of these methodologies and techniques ensures that ballistic vests provide maximum protection. Continuous research and development drive innovations in this field. Engineers strive to create vests that balance protection, comfort, and mobility. The use of advanced tools like Ansys and the FEM technique plays a pivotal role in achieving these goals.

Testing and Standards

Ballistic Testing

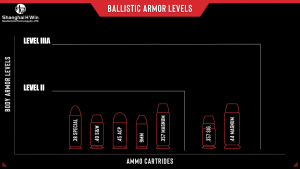

NIJ Standards

The National Institute of Justice (NIJ) sets the benchmark for ballistic vest performance. The NIJ standards classify vests based on their ability to stop specific calibers of bullets. Each level of protection undergoes rigorous testing to ensure compliance. Manufacturers must adhere to these standards to guarantee the effectiveness of their products.

Testing Procedures

Ballistic testing involves a series of controlled experiments. Engineers shoot various calibers of bullets at the vest to evaluate its stopping power. The tests measure the vest’s ability to absorb and disperse kinetic energy. High-strength materials like Kevlar and Dyneema play a crucial role in this process. The layering of these materials helps slow down and stop the projectile. The testing procedures ensure that the vest meets the required safety standards.

Quality Assurance

Manufacturing Standards

Quality assurance begins with strict manufacturing standards. Each stage of production undergoes meticulous inspection. Engineers ensure that the materials meet the specified requirements. The manufacturing process includes precise cutting, stitching, and assembly of the vest components. Consistency in production guarantees the reliability of the final product.

Field Testing

Field testing provides real-world validation of ballistic vests. Engineers conduct these tests in various environmental conditions. The vests undergo exposure to different stress factors, including temperature fluctuations and physical wear. Field testing ensures that the vests perform reliably under actual use conditions. The feedback from these tests helps refine the design and improve overall performance.

Future Trends in Ballistic Vest Engineering

Innovations in Materials

Nanotechnology

Nanotechnology promises significant advancements in ballistic vest materials. Engineers use nanoparticles to enhance the strength and flexibility of fibers. These particles improve the energy absorption capabilities of materials like Kevlar and Dyneema. The integration of nanomaterials results in lighter and more durable vests. Researchers continue to explore new applications of nanotechnology in protective gear.

Smart Materials

Smart materials represent another frontier in ballistic vest engineering. These materials can adapt to different conditions. Engineers design smart materials to change properties in response to external stimuli. For example, some materials harden upon impact to provide additional protection. Others may regulate temperature to enhance wearer comfort. The development of smart materials aims to create more versatile and effective ballistic vests.

Design Improvements

Enhanced Mobility

Enhanced mobility remains a critical focus in ballistic vest design. Engineers strive to create vests that allow for greater freedom of movement. The use of lightweight materials like Dyneema contributes to this goal. Adjustable straps and ergonomic designs further improve mobility. The aim is to ensure that wearers can perform their duties without restriction. Continuous research in material science and design methodologies drives these improvements.

Increased Protection

Increased protection is paramount in the evolution of ballistic vests. Engineers incorporate advanced materials to enhance the vest’s ability to stop high-velocity projectiles. The integration of ceramic and polyethylene plates provides comprehensive coverage. These plates disperse the energy from bullets, reducing the risk of penetration. Ongoing research focuses on developing new materials and designs to offer even higher levels of protection. Armour Industries are striving to achieve the perfect balance between protection and wearability.

The blog provided a comprehensive analysis of ballistic vest engineering. Key points included the historical evolution, materials used, and engineering principles. The significance of ongoing research and development cannot be overstated. Innovations in materials like nanotechnology and smart materials promise to enhance future vests. Design improvements aim to balance protection with mobility. The future of ballistic vest engineering looks promising, with continuous advancements ensuring better safety and comfort for users.