Bulletproof technology is vital in saving lives. Studies indicate that police officers not wearing ballistic armor face a 14-fold increase in the risk of fatal injuries. Over time, advancements in material science have revolutionized protective gear. From ancient armor to modern innovations, materials like Kevlar, SiC Ceramic, and Alumina Ceramic have become the best craftable bulletproof materials and common materials for bulletproof vests. Ultra-High-Molecular-Weight Polyethylene (UHMWPE) provides enhanced protection. These innovations underscore the evolution of bulletproof materials, ensuring safety and adaptability in various environments.

Ancient Armor

Early Materials

Leather

Leather served as one of the earliest forms of armor. Ancient warriors valued its flexibility and availability. They crafted leather into protective gear, which offered basic defense against weapons. Leather armor was lightweight, allowing soldiers to move freely in battle. Its use spanned various cultures, highlighting its importance in early warfare.

Metal

Metal armor marked a significant advancement in protection. Warriors began using metals like bronze and iron to create stronger defenses. Metal armor provided superior protection compared to leather. It included helmets, breastplates, and shields. This innovation played a crucial role in the evolution of military tactics and equipment.

Historical Context

Usage in Warfare

Armor has been integral to warfare throughout history. Roman legions, for example, utilized metal armor to protect soldiers in battle. Medieval knights wore suits of armor, combining metal plates with chainmail. These developments in armor technology reflected the changing needs of combat and the desire for enhanced protection.

Cultural Significance

Armor also held cultural significance. It symbolized strength and status. Knights’ armor, often ornate, represented their social standing and valor. Different cultures developed unique styles of armor, reflecting their traditions and technological advancements. Armor became more than just protection; it was a representation of identity and heritage.

Early 20th Century Developments

Introduction of New Materials

Cotton

In the early 20th century, the Army explored new materials for protective gear. Cotton emerged as a potential candidate due to its availability and ease of production. Soldiers found cotton comfortable and breathable, making it suitable for extended wear. However, cotton’s limitations in providing adequate protection against ballistic threats became evident. Despite its widespread use, cotton could not withstand high-velocity impacts, necessitating further innovation in protective materials.

Silk

Silk, a natural fiber known for its strength and flexibility, gained attention as a material for body armor. Scientific Research Findings: Gottfried Wilhelm Leibniz proposed using silk for protective fabric over three hundred years ago. The Army considered silk’s lightweight properties advantageous for mobility. Silk’s tensile strength offered reasonable protection, making it a promising option for early bulletproof vests. Despite its potential, silk faced challenges in mass production and cost-effectiveness, limiting its widespread adoption in military applications.

Technological Advancements

Impact on Protection

The introduction of new materials like silk marked a significant advancement in protective technology. Silk’s unique combination of strength and flexibility provided enhanced protection compared to traditional materials. Soldiers experienced improved mobility and comfort, allowing them to perform their duties more effectively. The Army recognized the potential of silk in crafting bulletproof vests, leading to further exploration of natural fibers for body armor applications.

Limitations

Despite the advancements, early 20th-century materials faced limitations. Cotton, while comfortable, lacked the necessary strength to stop bullets effectively. Silk, although stronger, presented challenges in terms of cost and scalability. The Army continued to seek materials that could offer superior protection without compromising on weight and flexibility. These limitations highlighted the need for ongoing research and innovation in the development of bulletproof materials.

Mid-20th Century Breakthroughs

Invention of Kevlar

Development Process

Kevlar emerged as a groundbreaking material in the mid-20th century. Stephanie Kwolek, a chemist at DuPont, developed it in 1965. Her work focused on creating a strong yet lightweight fiber. Kevlar’s unique molecular structure provided exceptional strength. This innovation marked a significant leap in body armor technology. Researchers recognized its potential for various protective applications.

Impact on Body Armor

Kevlar revolutionized body armor. Its strength-to-weight ratio surpassed previous materials. Soldiers and law enforcement officers benefited from enhanced protection. Kevlar allowed for more flexible and comfortable body armor designs. This advancement increased mobility and effectiveness in the field. The introduction of Kevlar set a new standard for safety and performance.

Other Innovations

Advancements in Body Armor Technology

The mid-20th century saw rapid advancements in body armor technology. Researchers explored new materials and designs. They aimed to improve protection without adding weight. Innovations included composite layers and advanced fibers. These developments enhanced the durability and effectiveness of body armor. The focus remained on providing maximum safety for users.

Introduction of Bulletproof Vests

Bulletproof vests became more common during this period. Manufacturers incorporated Kevlar and other advanced materials. These vests offered reliable protection against ballistic threats. They became essential for military and police use. The design of bulletproof vests prioritized comfort and flexibility. This innovation ensured that users could perform their duties with confidence.

Contemporary Materials

UHMWPE

Ultra-High-Molecular-Weight Polyethylene (UHMWPE), often referred to as UHMWPE, stands out as a revolutionary material in the realm of bulletproof technology. Its exceptional properties make it a preferred choice for crafting hard armor and bulletproof vests.

Advantages

UHMWPE offers several advantages that make it the best craftable bulletproof material. Its lightweight nature ensures that wearers experience increased mobility and comfort without compromising on protection. The high tensile strength of UHMWPE allows it to absorb and disperse the energy from bullets effectively, providing superior ballistic protection. This makes it a common material for bulletproof vests and other protective gear.

Applications

The applications of UHMWPE extend beyond just bulletproof vests. It is widely used in the manufacturing of bulletproof shields, helmets, and plates. Its versatility makes it suitable for various environments, ensuring safety and adaptability. UHMWPE’s role in modern armor technology highlights its significance in the evolution of protective materials.

Ceramics

Ceramics have emerged as a vital component in the development of modern armor. Among the various types, SiC Ceramic and Alumina Ceramic are particularly noteworthy for their unique properties.

SiC Ceramic and Alumina Ceramic

SiC Ceramic, or silicon carbide ceramic, is renowned for its high hardness and lightweight characteristics. It provides excellent protection against high-velocity projectiles, making it an ideal choice for hard armor applications. Similarly, Alumina Ceramic offers superior durability and strength, ensuring long-lasting protection in critical situations.

Benefits

The benefits of using SiC Ceramic and Alumina Ceramic in armor are manifold. These materials provide robust defense without adding excessive weight, allowing for enhanced mobility. Their ability to withstand high temperatures and impacts makes them indispensable in the design of modern bulletproof equipment.

Usage in Modern Armor

In contemporary armor, SiC Ceramic and Alumina Ceramic play crucial roles. They are commonly used in bulletproof vests and shields, providing reliable protection against ballistic threats. The integration of these ceramics into armor designs underscores their importance in the ongoing evolution of bulletproof materials.

HWIN’s Role in Bulletproof Supply Store

HWIN has established itself as a leader in the bulletproof supply store industry, offering a wide range of high-quality products. The company prides itself on delivering the best craftable bulletproof material to meet diverse protection needs.

Best Craftable Bulletproof Material

HWIN’s commitment to innovation ensures that they provide the best craftable bulletproof material available. Their products, including UHMWPE and ceramics, are designed to offer maximum protection while maintaining user comfort and mobility.

Common Material for Bullet Proof Vests

In the realm of bulletproof vests, HWIN’s offerings stand out for their reliability and effectiveness. The use of common materials like UHMWPE and ceramics in their products ensures that customers receive top-tier protection. HWIN’s dedication to quality and customer satisfaction makes them a trusted name in the bulletproof supply store market.

Future Innovations

Emerging Materials

Spider Silk

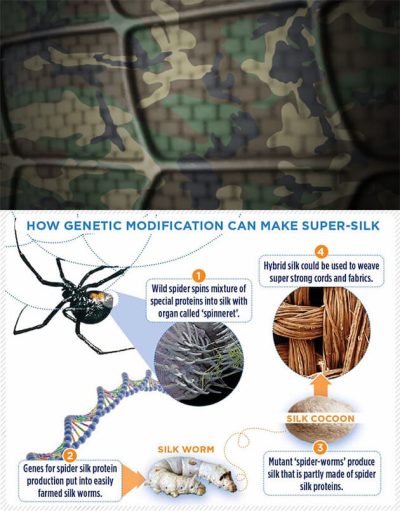

Spider silk represents a groundbreaking material in the future of armor technology. Researchers have discovered that spider silk surpasses traditional bulletproof materials in strength and flexibility. Its unique properties make it an ideal candidate for creating lightweight and durable protective gear.

Scientific Research Findings:

- Spider silk exhibits a higher strength-to-density ratio than steel.

- It combines tensile strength with extensibility, outperforming many fabricated materials like Kevlar.

Scientists have even engineered spider silk fibers using genetically-modified silkworms, paving the way for scalable production. This innovation could lead to the development of bulletproof vests and other protective equipment that offer superior protection without added weight.

Properties of Spider Silk

The properties of spider silk make it a fascinating subject for materials researchers. It is not only tough but also sustainable, offering a renewable resource for future innovations. The silk’s ability to form a bulletproof mesh highlights its potential in various applications, from military gear to civilian safety equipment.

Ongoing Research

Upcoming Body Armor Technology

Ongoing research into spider silk continues to reveal its potential in body armor technology. Scientists are exploring its use in creating more effective and adaptable protective gear. The focus remains on harnessing spider silk’s remarkable properties to enhance safety and performance.

History of Spider Silk

The history of spider silk dates back centuries, with its use in textiles and other applications. Today, its potential extends far beyond traditional uses. Researchers are investigating its applications in airplanes, surgical threads, implants, and prostheses. This exploration underscores the versatility and promise of spider silk in modern technology.

The evolution of bulletproof materials showcases a remarkable journey from ancient leather and metal armor to modern innovations like Kevlar and ceramics. Each advancement has enhanced protection and adaptability. HWIN continues this legacy by offering cutting-edge products, including soft body armor vests, UHMWPE, and ceramics. Their commitment to quality and innovation ensures top-tier protection. Explore HWIN’s offerings to discover the latest in bulletproof technology and secure reliable safety solutions.